Finnish Marttiini knives

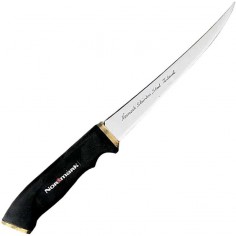

Are you looking for a fixed blade knife? Finnish Marttiini knives, from everyday knives to tactical and hunting knives, select and you will find what you need.

It all started in 1928 when a blacksmith Janne Marttiini decided to set up a knife factory in the town of Rovaniemi in Finnish Lapland.

With the user in mind, he began to create beautiful, high-quality utility items to be used in the harshest conditions imaginable.

Marttiini knives are still made in the Arctic Circle. Today they are a combination of generations of craftsmanship and modern technology that create knives that are not only sharp, but also perfectly represent the beauty and hardness of the North. They are called "puukko" - the Nordic knife.

Marttiini knives and razors have been made in an Arctic environment since Janne Marttiini founded the factory in 1928. They are products of a prestigious tradition and are known throughout the world.

Marttiini knives stand out for their durability, elegant designs and high quality, making them the perfect choice for many craftsmen and hunters.

The Marttiini brand of knives and razors is undoubtedly one of the leading manufacturers of quality knives for fishing and hunting.

Janne Marttiini was a blacksmith born in a small village called Kierinki in northern Finland. He made scythes, axes, small tools and handmade knives. In 1928 he founded his own smithy in Rovaniemi and developed excellent models of knives and methods for their manufacture. The demand for these strong, high-quality knives increased continuously during the 1930s and Janne Marttiini was able to support his large family by making knives and razors.

In 1940 a factory was built, which was partly destroyed during World War II in 1944, but was later rebuilt in the centre of the town of Rivaniemi. Today this factory has been restored and has been converted into a museum.

Marttiini knives are known worldwide.

Janne Marttiini with his family. Marttiini founded his own knife and blade company in 1928 in Rovaniemi, Finland.

Due to steady growth in the export business, it became necessary to expand the facilities. In 1972 a modern new plant was built. Today it employs 65 people and is run by the third Marttiini generation of the family.

Today Marttiini manufactures over 300 different models of knives, ranging from the original Lynx knife made by Janne Marttiini to models with the latest technology and raw materials. The Marttiini catalogue contains knives for hunting, fishing, camping, home, professional and collector's use. The manufacturing process still retains the features of the traditional hand-made production of the past, incorporating the research and development of today.

The daily production is around 5,000 knives and razors, ensuring deliveries of large quantities to different countries in the world such as the USA, Canada, Germany, Great Britain, the Scandinavian countries or Australia.

The competition both at international and national level is very strong. High quality, long experience, tradition, special knowledge in the production of knives and razors combined with continuous research and efficient development make the Marttiini brands one of the most competitive on the knife market.

The blade of Marttiini knives and razors is world famous. Its good reputation comes from the Marttiini special steel and the high quality of the manufacturing process.

The blades are made of a special stainless chrome steel. Numerous studies and tests have been carried out to achieve the right combination of molten chrome with other materials.

The tempering process at the ideal temperature ensures a strong and durable blade. The composition of the materials (containing 13% chrome which ensures that the steel is completely stainless, durable and resistant to salt water and acid) tempered between 54 and 56 on the Rockwell hardness scale (HRC) is the best combination for the manufacture of the blades of knives and razors. With a blade tempered below 54 HRC it would be easier to sharpen but would not be durable and the blade edge would be too flexible for demanding use. Tempering above 56 HRC would give the blade greater hardness but it would break more easily.

Marttiini currently orders its steel from mills in Germany and France. In the manufacturing process, the sheet is finished by means of rollers, which change the arrangement of the molecules from a circular to an elliptical shape.

This process makes the metal composition denser and therefore makes the sheets more durable and flexible and the edge noticeably longer.

In Rovaniemi the tempering of the leaf finishes goes through 7 different phases until the leaf is ready to be polished by hand in the final step. The blades are always machine-sharpened. This machine adjustment requires the utmost care and time, and requires very high skill in sharpening blades.

Marttiini blades are well known to lovers of hunting, fishing, camping, etc...

Marttiini Knives is constantly researching to achieve the best possible quality in the blades, handles and sheaths of its knives and razors, as well as in their assemblies and opening and closing systems.

All the handles used on Marttiini knives are manufactured directly by Marttiini at its locations in Laukka and Rovaniemi.

Various types of wood are used to manufacture the handles. The handles are traditionally made of curly birch wood from Finland. The curly birch used in the handles of Marttiini knives and razors only grows in areas of central Finland. This hard material is very suitable for knife handles, as it is durable, beautiful and in demand. Due to limited availability this wood is more valuable than ordinary Finnish birch wood, which is another material also used in large quantities. To meet the demands of international markets, Marttiini has for years used other dark-toned woods such as hazelnut or rosewood. These beautiful woods give the knife a higher value.

As a company based in Lapland, Marttiini has always wanted to highlight the traditions of this region and exotic Arctic art. These features have inspired designers in their development of collector's knives. These decorative Marttiini knives and razors have a rich combination of materials, reindeer horn bone and curly birch wood. The handmade handles are decorated with engravings and a mythological bell inside the horn bone to chase away evil spirits. Each knife and blade is an individual masterpiece.

Marttiini Knives has worked hard to find a good and durable cover for the wooden handles. For the best grip and protection of the handle all wooden handles are coated with lacquer or oil.

This layer also protects the handles from moisture and dirt. Marttiini uses two different types of lacquer: cellulose lacquer or the new plastic lacquer. Cellulose lacquer is durable, widely used and gives the handles a light yellow colour. The new plastic lacquer is non-toxic, made from water-soluble materials and used for new models such as the Golden Lynx. This lacquer retains the colour of light coloured woods well. The oil coating is more suitable for the handles of noble woods of knives such as Bird or Deer. The oil protects the handles but also ensures a good grip.

Over the last ten years, plastic, rubber and their combinations have been gaining ground. They are ideal for handles, as plastic and rubber handles are easy, favourable and quick to make. These materials perform and meet the requirements perfectly in wet conditions. These handles are also hygienic, safe, firm and have a strong grip. These combinations offer different gripping sensations: softer if there is more rubber and more solid if there is more plastic.

The ferrules hold the handle and blade together, covering the holes in the wood and the rivets. The materials used are nickel, brass, bronze, copper and now also plastic.

The sheath of the Marttiini knives and razors covers and protects the knife and also the user to prevent injury. Marttiini has created the right sheath for each of its knife models. The sheaths are reinforced by means of rivets on their edges, inlayed rivets, and others placed around the sheath or the plastic inner part of the sheaths.

The most commonly used material in the covers of Marttiini knives and razors is bull skin. To find the best quality leather, Marttiini dedicates many hours of work and numerous tests. Today the material used in the covers of Marttiini knives and razors comes from Italy and Spain. The leather cases are made entirely by hand. The cases are sewn using the milk glue to keep the edges tightly closed.

To offer a wide selection of products Marttiini uses alternative materials for its cases as well. The plastic covers are manufactured to be resistant even to water. These covers are very practical and protect the knife perfectly. They are available in various colours.

Every Marttiini knife and razor goes through a careful quality control where it is engraved on its blade J Marttiini, Finland.

Today Marttiini produces around 300 different models of knives and razors, from the original Lynx, made by Janne Marttiini, to modern designs using the latest technology and raw materials. The Marttiini knife catalogue includes hunting, fishing, camping, collector's, household and industrial knives and blades.

English

English  Español

Español Deutsch

Deutsch